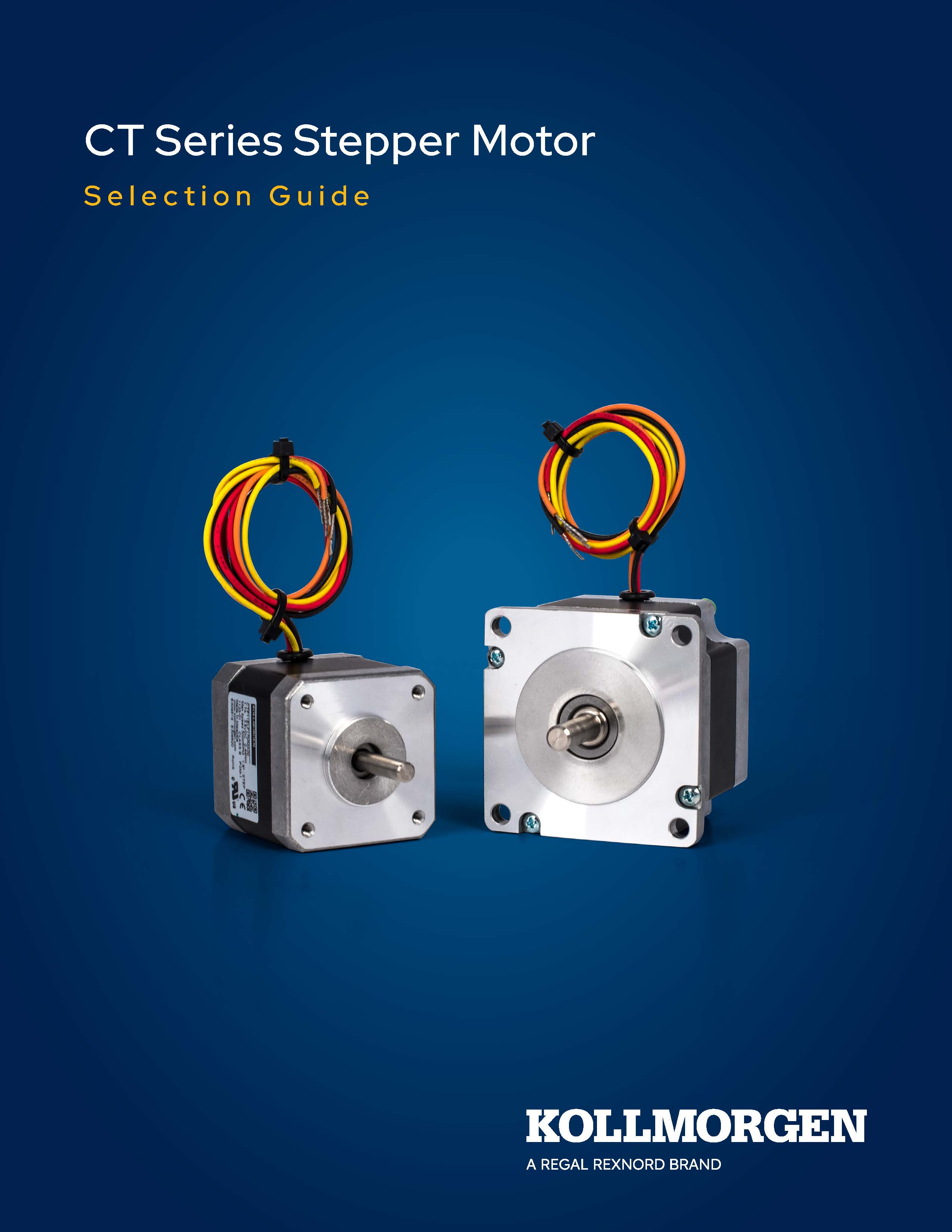

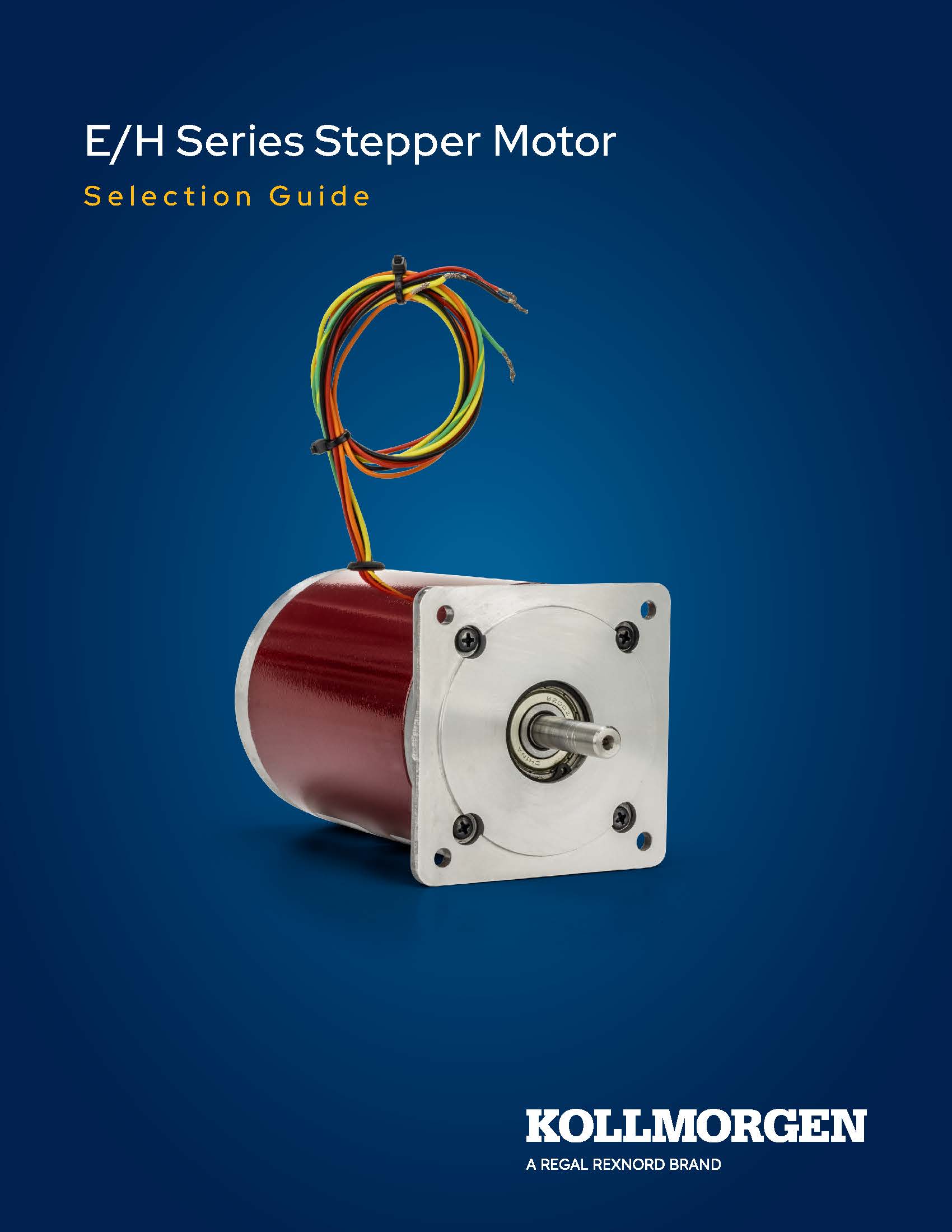

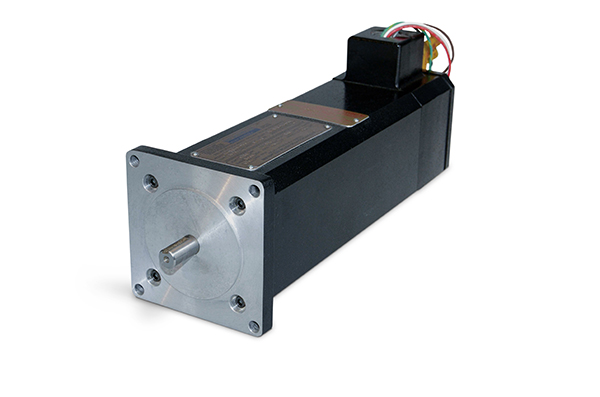

Kollmorgen’s stepper motors are designed with versatility, ease–of–use, and cost-effectiveness in mind. They provide high torque in a small package and come in a wide range of standard sizes, constructions, windings and options.

Kollmorgen’s stepper motors are designed with versatility, ease–of–use, and cost-effectiveness in mind. They provide high torque in a small package and come in a wide range of standard sizes, constructions, windings and options.

to view this Document

to gain access to Kollmorgen content

An aging population, a growing burden of disease, continuous development of new clinical applications, and global advancements in the standards of disease prevention, early detection, diagnosis and treatment. For all these reasons and more, manufacturers of diagnostic imaging equipment are under extraordinary pressure to produce more innovative machines, capable of more precise imaging, delivered to healthcare institutions of every size, kind and location.

This article presents an overview comparison of stepper motor and servo motor capabilities to serve as selection criteria between the two technologies.

Learn how to engineer exceptional machines, robots and vehicles with the highest-performing, most reliable motors, drives, automation solutions and more.