Cost pressures and production quotas are tough enough to meet. Products also have to be different and better to stand out in a crowded marketplace. The competition for innovation, appeal and quality at the point of sale is reflected in an intense competition for machines that can apply more sophisticated processes, with higher throughput, less waste and minimal downtime.

Cutting, folding and forming processes need to be precise. Changeover needs to be fast and flexible. Errors need to be minimized and, when they do occur, need to be fixed as quickly as possible with minimal scrap. Machines need to be low-maintenance and upgradable to accommodate new products and higher production goals. Kollmorgen motion solutions and expertise make the difference.

Labeling >

Precise positioning and torque is the key to creating and applying flawless labels, faster. Advanced automation allows labeling machines to do more.

Form Fill & Seal >

From accurate portioning to creating a reliable seal, product consistency and quality depends on accurate motion control at high production speeds.

Cartoners >

Whether a lightweight product display or a heavy-duty transportation box, it takes fine-tuned torque and velocity to form and pack cartons perfectly.

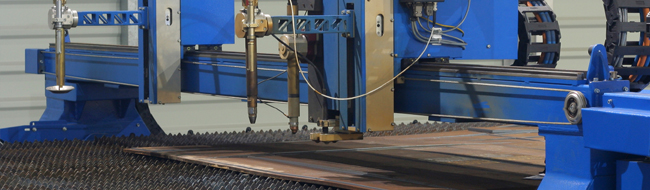

Die Cutting and Laminating >

Processing webs of material that can vary dramatically in size, weight and strength requires infallible control over wide torque and velocity ranges.

Flexible Packaging >

From high-speed registration to advanced motors & drives, our complete system solutions create perfect motion across any machine process to increase speed, precision and productivity.Engineer the Exceptional

Learn how to engineer exceptional machines, robots and vehicles with the highest-performing, most reliable motors, drives, automation solutions and more.